7 Minute read

Why Venture Engineering Switched from Spreadsheets to Acumatica ERP – and Never Looked Back

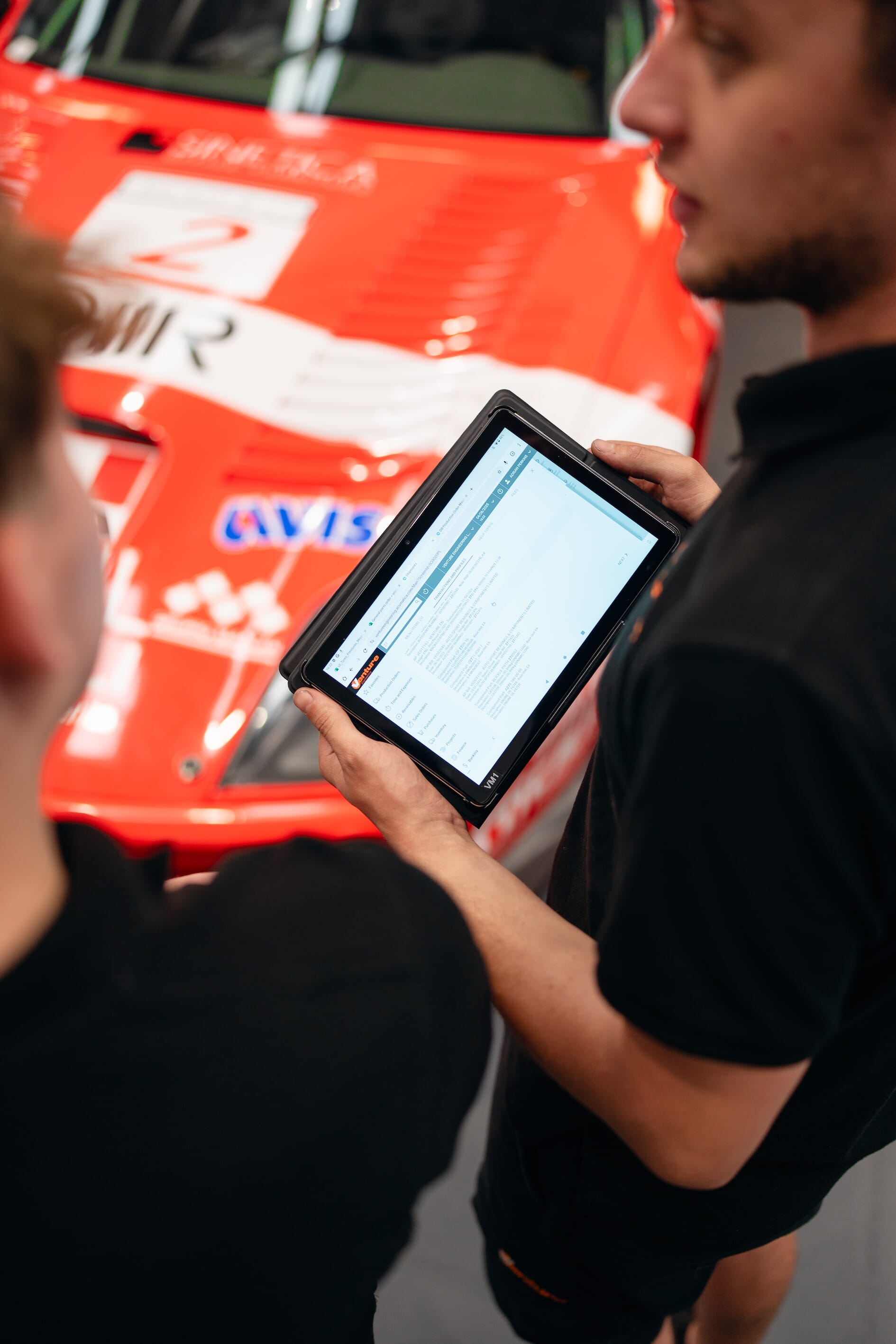

For Venture Engineering, precision is everything. When they switched from spreadsheets and Quickbooks to Acumatica integrations with Cedar Bay, it got them into a winning streak. Here's why it was a game-changer...

Roger Teagle

3rd Oct 2025

When Venture Engineering launched in 2015 as a five-person motorsport start-up, the team ran the operation on QuickBooks and spreadsheets. As the company grew with new hires and dozens of projects running at any one time, it soon became apparent that a more substantial system was needed to stay ahead of the game. 10 years later, Acumatica now fuels the team’s success.

From spreadsheets to single source of truth

Before switching to Acumatica, Venture Engineering had eight people who were tied up full-time maintaining spreadsheets for F1 clients. Inventory was ‘managed’ by walking into the warehouse and counting parts. Bills of materials didn’t exist, so labour and materials often slipped through the net.

“Trying to track some of the bigger projects was just becoming an absolute nightmare,” says co-founder and Operations Director Adrian Perkins. “The simplicity of QuickBooks didn’t allow us to input enough detail to get the right information out at the other end. The data we had was actually pretty useless.”

For a business built on engineering precision, this system of operating was anything but precise.

When precision matters, spreadsheets don’t cut it

Motorsport is a world where milliseconds matter, and accuracy is non-negotiable. That’s why Venture’s old way of working needed to be streamlined to be able to compete on the world stage.

Venture Engineering pre-Acumatica:

- No historical data: Quotes were based on guesswork instead of hard data.

- No tracking of labour: This made it hard to justify costs to customers.

- No confidence in costs: Projects looked profitable on paper but bled margin in reality.

- No real-time inventory tracking: Tracking was entered manually on a spreadsheet that wasn’t updated regularly and was never accurate.

The team knew they needed a system that matched their customers’ high standards – one platform to bring finance, inventory, projects, and reporting into focus.

Why Acumatica ERP? For flexibility and functionality

As the company grew, it became harder to track hours spent on specific projects accurately. “It was almost like a bit of a finger in the air at the end of the job trying to capture all the time that different people and different departments would put in,” says co-founder and Manufacturing Director, Joe Lofthouse. “Now every member of the staff inputs a time sheet at the end of every week.”

The Venture Engineering team initially reviewed larger ERP systems they’d used at previous companies, but most were too heavy and rigid. Acumatica struck the balance: a modern, cloud ERP with the manufacturing depth they needed – MRP, stock control, project accounting – plus the Acumatica integrations to connect workflows across the business.

Joe agrees that Acumatica implementation has brought significant improvements. “From where we were at the start to where we are now is just mind blowing,” he says. “The sort of exponential growth has increased massively since we’ve had the software.”

“From day one, it felt very flexible and easy to customise to what we wanted,” says Adrian. “Other options were rigid. Acumatica’s flexibility definitely drew us in.”

A phased Acumatica implementation that changed everything

Motorsport is constantly evolving, with teams always looking to develop advanced technologies that can eke out every last bit of detail from live, on-the-track data. This was no different.

With Cedar Bay as their Acumatica partner, Venture Engineering set out a phased implementation strategy over 3–6 months: purchasing, finance, and inventory first; then project accounting, production orders, and reporting.

Phil Moss, Finance Manager, joined Venture Engineering after Acumatica was deployed. Like others, he found it easy to learn, user friendly, and intuitive. He liked Acumatica’s ability to drill down and quickly trace transactions and is building custom dashboards for the business.

“The key for us now is getting used to having the information and how can we then make best use of that,” he says. “We are not used to having all that detail available, which is now something that we can learn and grow from.”

Results: visibility + traceability = a winning formula

Replacing fragmented spreadsheets with a single, connected platform meant that Venture Engineering was soon in pole position. Thanks to Acumatica integrations, they now operate with more precision, more speed and more control over their business.

Venture Engineering post-Acumatica:

- End-to-end visibility across 50+ live projects.

- Accurate BOMs and labour tracking to understand true project costs.

- Improved quoting with access to historical project data.

- Inventory control that replaces guesswork with real-time data.

- Customer transparency via controlled access to project status.

- Reduced admin burden, freeing the eight ‘spreadsheet managers’ to add real value elsewhere.

Since switching to Acumatica, the Venture Engineering team has gone on to operate in triple its initial space, diversified into new markets, and engineered its own GT4 race car that won the series crown in 2024, its maiden year.

“It’s been a game-changer,” says Adrian. “Acumatica has completely transformed the business and has just made everyone’s life so easy.”

Venture Engineering x Acumatica: Quick FAQs

1) What benefits does ERP for manufacturers have over spreadsheets and QuickBooks?

Alongside providing a more complete finance solution, the platform integrates all departments of the business into a single system. This delivers full visibility of operational activities and, in areas such as manufacturing, enables better planning and scheduling to improve overall effectiveness. Spreadsheets/entry-level tools lack traceability and integration, causing errors, delays, and margin leakage.

2) How did Acumatica ERP help Venture Engineering overcome spreadsheet challenges?

Switching to a cloud-based ERP system helped Venture Engineering to streamline their operations and data. With Acumatica ERP software, labour, inventory, BOMs and costs can now be updated in real-time in one system, meaning more end-to-end visibility.

3) Can Acumatica replace QuickBooks for manufacturers?

Yes. For MRP, project accounting, job costing, and multi-location inventory, Acumatica is a scalable step-up.

4) How long does an Acumatica with Cedar Bay implementation take?

It depends on scope, but we worked with Venture Engineering to implement the core functions of purchasing, inventory and finance in a phased deployment over 3 months. We then added functionality, including project accounting, production orders, and more reporting, gradually over the rest of the year.

5) What are the signs it’s time for manufacturers to move on from spreadsheets?

Data duplication, manual reconciliations, limited reporting, inaccurate quoting, siloed teams, lack of transparency, and reliance on institutional knowledge – these are some of the key indicators that manufacturing companies have outgrown their old systems and should consider a more sophisticated cloud-based ERP system like Acumatica.

Want to know more about Venture Engineering’s winning streak?

To find out more about the winning partnership between Venture Engineering and Acumatica ERP, read our blog, Accelerating Innovation: Cedar Bay at Silverstone with Acumatica and Venture Engineering.

If you’re interested in learning how Acumatica implementation can transform your operations, why not book a discovery call with Cedar Bay? We’ll scope your requirements and show you how Acumatica integration can boost your business.