7 Minute read

Six Common Challenges in Manufacturing and How Acumatica Integrations Address Them

Acumatica integrations are designed to help manufacturers overcome operational hurdles that could be holding their business back...

Roger Teagle

5th Feb 2026

Manufacturers today are under constant pressure to improve efficiency, control costs, and respond faster to customer demand. However, many organisations are still held back by disconnected systems, manual processes, and limited visibility across their operations.

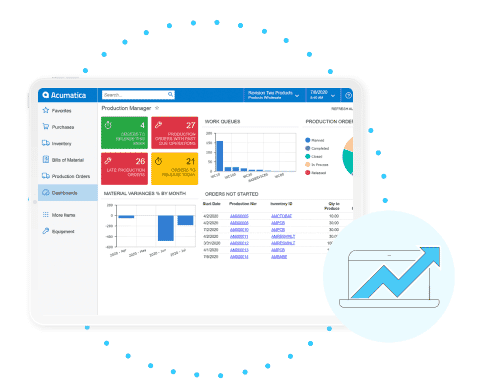

Acumatica integrations help address common manufacturing challenges by providing a unified, real-time ERP platform that connects core business functions. By integrating financials, inventory, production, and third-party systems, manufacturers can streamline operations, reduce manual effort, and gain clearer visibility across the supply chain. Here’s how…

Common manufacturing challenges – and how Acumatica integrations address them

Manufacturers often face similar operational hurdles as they grow or modernise. Acumatica integrations are designed to address these manufacturing challenges head-on:

1. Data Silos and Disconnected Systems

Challenge:

Many manufacturers operate multiple systems for accounting, inventory, CRM, and production, leading to fragmented data and inconsistent reporting.

Solution:

By acting as a central system of record, Acumatica brings together data from across the organisation and integrates seamlessly with specialist third-party systems. This helps manufacturers eliminate silos and gain a clearer, more consistent view of their operations, including:

- Reduced duplicate data entry and fewer inconsistencies between systems

- Improved cross-department visibility through shared, real-time information

- Seamless integration with CRM, WMS, and other specialist manufacturing applications via open APIs

- More accurate and consistent reporting across the entire business

This was the case for Venture Engineering, a motorsport manufacturing business that was struggling to manage multiple spreadsheets and disconnected systems across its operations. By switching from spreadsheets to Acumatica for Manufacturing ERP, the team gained greater visibility across finance, inventory and production, leading to a more reliable insight into day-to-day operations and sustained company growth.

“It’s been a game-changer. Acumatica has completely transformed the business and has just made everyone’s life so easy.”

Adrian Perkins

Venture Engineering Co-Founder & Operations Director

2. Manual Processes and Human Error

Challenge:

Manual data entry and spreadsheet-based processes increase the risk of errors and consume valuable staff time.

Solution: Automation reduces error and improves data accuracy while allowing teams to focus on higher-value tasks. Read more about the benefits of moving from manual systems to a Cloud ERP in our blog, From Spreadsheets to Cloud ERP: An Acumatica User Guide.

Acumatica supports workflow automation across sales, inventory, purchasing, and production, including:

3. Limited Real-Time Visibility for Decision-Making

Challenge:

Delayed or incomplete data makes it difficult for managers to make informed decisions about production planning, inventory levels, and cost control.

Solution:

With real-time transaction processing and configurable dashboards, Acumatica improves visibility across manufacturing operations and finance, helping decision-makers respond faster and with greater confidence. Key benefits include:

4. Inefficient Inventory and Supply Chain Management

Challenge:

Managing complex Bills of Materials (BOMs), material availability, and production timing can be challenging without integrated systems.

Solution: These capabilities help manufacturers to improve accuracy in material and warehouse management, product costing and inventory levels.

Acumatica supports quality and compliance processes through configurable workflows, document management, and audit trails, including:

5. Scalability and Flexibility

Challenge:

Legacy systems often struggle to scale as manufacturers grow or adapt to changing market demands.

Solution:

Acumatica’s open, cloud-based architecture provides:

- High scalability without infrastructure constraints

- Customisable workflows

- Seamless integration with third-party systems such as WMS, CRM, or eCommerce platforms

This flexibility supports long-term growth and digital transformation.

6. Quality Control and Compliance Management

Challenge:

Maintaining consistent product quality and meeting regulatory requirements can be difficult to manage manually across multiple systems.

Solution: This allows issues to be identified early, reducing risk and improving compliance.

Acumatica integrations support quality management with:

Key features of Acumatica Cloud ERP for Manufacturing

Acumatica’s Manufacturing Edition includes a robust set of tools designed to support production-focused businesses, while its open architecture allows manufacturers to extend functionality through configuration and integrations where required. Key features include:

Intelligent Inventory Management

Through native inventory functionality and integration with procurement and warehouse processes, manufacturers can have real-time visibility across the business to make more informed decisions.

Advanced Production Planning & Scheduling

Scheduling capabilities can be tailored through configuration to help manufacturers align production orders with material availability and balance capacity.

Real-Time Analytics & Reporting

Dashboards and reports are configurable, giving stakeholders access to manufacturing KPIs most relevant to their role.

Seamless Financial Management

Financial management is a core strength of Acumatica and allows manufacturers to gain a clearer view of true product and operational costs.

Cloud-Based Accessibility & Mobile Use

As a cloud-based ERP, Acumatica allows authorised users to securely access data from anywhere, with mobile-friendly screens and role-based access support.

The future of manufacturing with Acumatica

Supporting integrated digital transformation

The manufacturing sector continues to adopt technologies such as automation, connected devices, and advanced analytics. Acumatica’s open platform is designed to support this evolution by enabling manufacturers to:

- Integrate with IoT-enabled equipment and monitoring tools

- Leverage analytics and emerging technologies through third-party solutions

- Evolve alongside changing operational and market requirements

Rather than locking businesses into rigid processes, Acumatica provides a flexible foundation that can adapt as third-party integrations continue to be developed.

FAQs: Acumatica Integrations

What types of systems can Acumatica integrate with?

Acumatica integrates with a wide range of third-party systems, including Microsoft 365, CAD systems such as SolidWorks and AutoCAD, ecommerce platforms such as Shopify and BigCommerce, and CRM.

Is Acumatica suitable for small and mid-sized manufacturers?

Yes, Acumatica is commonly used by small to mid-sized manufacturers that need a more personalised approach along with the flexibility, scalability, and strong financial control they need to grow.

Do all manufacturing features work out of the box?

Yes, Acumatica is a fully-featured manufacturing system for most manufacturers but the simple integration options allow access to a huge variety of specialist options where companies need something more to support their businesses.

Working with an experienced Acumatica Gold partner in manufacturing will help ensure the system is aligned to your specific manufacturing processes. For more about this, take a look at our blog, Why a Sector-Specific ERP Partner can Help Accelerate Your Growth.

Choosing the right integrations for your manufacturing business

Acumatica Cloud ERP offers a vast number of integrated solutions and services to meet the business needs of small to mid-sized manufacturers. The key is to configure your platform with the right integrations to improve efficiency in your business.